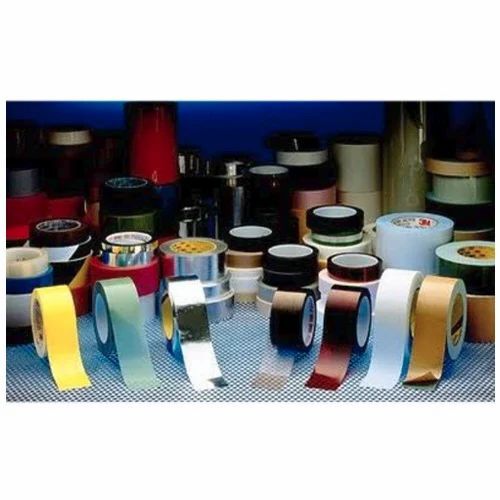

Packaging Tapes

Price 20 INR/ Piece

MOQ : 25 Pieces

Packaging Tapes Specification

- Product Type

- Packaging Tape

- Material

- BOPP (Biaxially Oriented Polypropylene) / PVC / Kraft Paper

- Type

- Self-adhesive Tape

- Style

- Single Sided

- Packing Format

- Roll

- Hardness

- Flexible

- Tensile Strength

- High, typically 35-50 N/cm

- Size

- 2 inch, 3 inch, Custom sizes available

- Dimension (L*W*H)

- Various lengths, commonly 50m to 650m

- Color

- Transparent, Brown, Other colors on request

Packaging Tapes Trade Information

- Minimum Order Quantity

- 25 Pieces

- Delivery Time

- 5 Days

- Main Domestic Market

- Gujarat

About Packaging Tapes

Specifications:

| Usage/Application | Industrial |

| Brand | Wonder, Acro |

| Packaging Size | Standard |

| Material | Bopp |

| Color | Transparent |

| Packaging Type | Box |

| Length | customized |

| Thickness | customized |

We are the foremost organization in the industry, engaged in offering the best quality Packaging Tapes.

Versatile Packaging Solution

Our single-sided packaging tapes are engineered to handle a variety of applications including sealing, packing, carton closure, and bundling. Their high tensile strength and flexibility ensure secure and efficient usage, whether you run a retail outlet, trading business, or wholesale operation.

Customizable Features and Dimensions

Choose from a wide range of sizes, thicknesses (38-60 microns), and lengths (10-650m) to suit your specific packaging needs. Options for core diameters and colors, along with custom branding and printability, provide enhanced personalization and brand visibility for your packages.

Reliable Performance and Longevity

Made from BOPP, PVC, or Kraft Paper and available in acrylic, hot melt, or natural rubber adhesives, these tapes deliver strong adhesion and resistance to heat up to 60C. Proper storage in cool, dry places extends shelf life up to 2 years, ensuring lasting performance and reduced waste.

FAQ's of Packaging Tapes:

Q: How do I choose the appropriate adhesive type for my packaging tape needs?

A: Selecting the right adhesive-acrylic, hot melt, or natural rubber-depends on your application requirements. Acrylic adhesives are ideal for long-term carton sealing and offer moderate UV resistance, while hot melt adhesives provide superior bonding on corrugated surfaces. Natural rubber is preferred for surfaces with varying texture or temperature.Q: What are the recommended storage conditions for maintaining tape quality?

A: To preserve the adhesive properties and extend shelf life up to 2 years, store packaging tapes in a cool, dry place away from direct sunlight and heat sources. Optimal storage helps prevent drying, degradation, or loss of tackiness.Q: When should I opt for custom printed branding on my tapes?

A: Custom printed tapes are beneficial when you want to enhance brand recognition, improve security, or communicate information on your packaging. Printing is best requested for promotional campaigns, product identification, or when branding consistency is important across shipments.Q: Where can these packaging tapes be used effectively?

A: These tapes are widely used in retail packaging, trading shipments, wholesale carton closure, and general warehouse bundling operations across India. Their robust adhesion and flexible formats make them suitable for various industries and packaging processes.Q: What is the typical process for applying self-adhesive packaging tape?

A: Use a tape dispenser or manually press the tape along the seam of cartons or bundles. Ensure surfaces are clean and dry for optimal adhesion. Press firmly to bond the tape securely; the tape's elongation and tensile strength provide reliable closure during transit and handling.Q: How does heat and UV resistance benefit my packing operations?

A: Moderate resistance to UV and heat (up to 60C) ensures that tapes maintain their adhesive strength and appearance even under challenging storage or shipping conditions, reducing risks of tape failure in hot or brightly-lit environments.Q: What are the major benefits of using flexible, single-sided self-adhesive tapes for packaging?

A: Flexible, single-sided tapes offer high tensile strength, custom sizing, convenient roll format, and reliable bonding. This simplifies bundling, sealing, and carton closure tasks while accommodating a wide range of pack sizes and materials.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Packaging Tapes Category

BOPP Tapes

Price 25 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Different Size Available

Product Type : Other, BOPP Tapes

Hardness : Soft

Color : White, Brown

|

PAYAL ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry